- Zhejiang Hengyou Machine & Electron Co., Ltd.

- E-mail:

sales4@chinahengyou.com.cn - CONTACT US

Hengyou’s manufacturing facility consists of 6 workshops (metalworking workshop, heat treatment workshop, painting workshop, injection workshop, motor workshop and assembly workshop). All essential parts are manufactured in-house, allowing us to maintain greater control over the quality of our products. Our manufacturing department is staffed by 430 highly trained employees. We constantly update our workshops, technology, and equipment. We use over 500 precision devices along with senior professional technicians to optimize production quality in every procedure.

We perform strict incoming quality control procedures on our incoming materials from providers. This includes testing materials according to blueprints and specifications, to ensure production quality on the incoming side.

The heat treatment workshop performs heat treatment procedures on iron components and gears of rotary hammers and demolition hammers. In 2015, we spent ¥15 million (about $2.23 million) to update our heat treatment equipment, along with professional testing and measurement equipment, for better efficiency during production and better quality of our products.

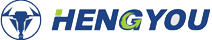

Our metalworking workshop is mainly applied for the magnesium aluminum cases of our rotary hammers and demolition hammers as well as gears with low modules. The workshop is equipped with precision machining centers, CNC turning machines, CNC hobbing machines, crawler-type ultrasonic cleaners, etc. We have over 40 tapping centers of different types (UT380, UM450, GM700D, etc.); We apply a precision CMM device for measurement, to ensure manufacturing accuracy.

DISC electrostatic coating equipment of our painting workshop is capable of painting and coating more evenly, the coat features better adhesion, thus we have better quality control.

The injection workshop is outfitted with 10 injection devices, over 600 kinds of molds, and can complete the injection molding of plastic cases of our rotary hammers and demolition hammers. The workshop completes surface treatment on plastic, to achieve better appearance and quality.

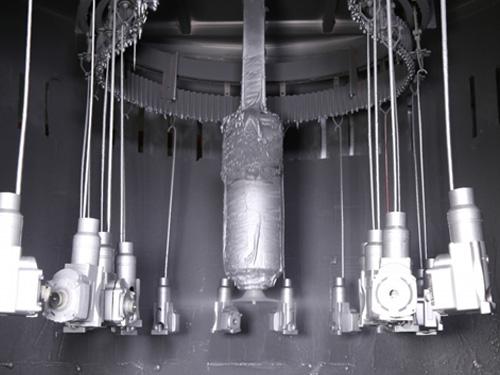

Our motor workshop mainly provides stators and rotors for rotary hammers and demolition hammers. Our equipment includes: automatic stator winder, dual station automatic balancing machine, automatic rotor winder, stator/rotor trickle impregnation machine, automatic grinder, frequency variable spot welder, coil former, precision turning machine, etc. We also have a professional electrical engineer and skilled manufacturing management personnel, to ensure the stability and quality of the motors.

For now there are 10 assembly lines in our assembly workshop, each line is equipped with advanced high voltage proof and anti-aging devices, to ensure assembly accuracy of every rotary hammer and demolition hammer. Production capacity of the workshop is 120,000 per month.

Hengyou is a professional rotary hammer and demolition hammer manufacturer that is experienced for over 30 years, with production power of 1.5 million per year. Hengyou owns two self-owned brands, “HENGYOU” and “PTG”, also provide OEM service according to customers’ requirements. Since establishment in 1988, we are dedicated to power tool developing and manufacturing, for now we have formed a complete manufacturing procedure. We’ve established professional technical team, manufacturing team, QA team, after service and support team, etc., choose Hengyou as your provider is a wise choice.

READ MORE